What is DTF Printing? – The Ultimate Guide

There are several popular printing techniques used to create custom clothing and other products, but which one is best suited for your business? Each printing process has special functions that work better with some materials or budgets than others. One of the most common printing types is dye sublimation printing while another popular format is DTF printing. But what exactly is DTF printing and how does it differ from other printing methods? Read below to find out its meaning, how it works, how it compares to other printing techniques, and its advantages/disadvantages to understand why many businesses use this printing source.

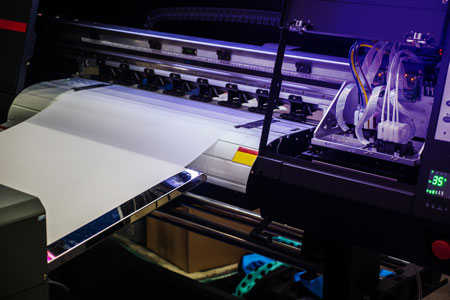

DTF Printing Meaning

DTF simply stands for Direct to Film. This is because your artwork is recreated directly onto a film and transferred onto fabric rather than being printed directly onto the material. The printed graphics have a textured feel to them compared to other printing methods where the ink is ingrained into the fabric. This type of printing is efficient when working on a wide range of materials compared to other printing methods. While some printing processes can only be used on polyester or cotton fabrics, DTF printing allows you to add your custom artwork to all kinds of cotton and poly blends (including synthetic, silk, fleece, and nylon), opening customization to more products and apparel. This includes bulkier fall and winter clothing. This printing process also allows you to print on different color fabrics rather than just white. If you are looking to increase your line of custom products and open your business to more customers, having a DTF printer is a smart investment.

A heat press is used for transferring the film artwork onto fabric. Special PET film is used because it has a coating that makes transferring the graphics easy. Water-based inks and an adhesive powder are also used when transferring the print. The white powder adhesive binds the color pigments, resulting in vibrant, striking color reproduction. While DTF printing incorporates full CMYK colors, white ink is used as the foundation of the artwork, creating stunning, colorful custom artwork. Because this type of printing doesn’t require heavy or overly expensive machinery, this printing process is more affordable than other options, making it easier to attain a positive return on investment for small and large businesses.

DTF Printers and How They Work

To understand what you need for printing your garments, it’s important to know how DTF printers actually work. The entire process only requires a few steps.

- The first thing you need is PET film and powder adhesive. The film is secured in the printer.

- The printer will add color to the film and then a white layer.

- Next, the adhesive is added to the ink while it’s still wet.

- Before being transferred to fabric, heat the film using either a heat press or a curing oven. Keep it in the heat press for 2-5 seconds. This will flatten the film so it can be pressed on the fabric.

- Next, the heat press is used to transfer the film artwork onto the fabric by pressing it for 15-20 seconds at 165°C.

- When you are finished transferring the design, peel the film off.

- Use the heat press to flatten the design again to ensure a long print life.

These few steps are all it takes to successfully recreate your artwork onto a garment so that it’s ready to ship or wear.

DTF Printing vs DTG Printing – The Big Differences

This DTF printing process is different from the one used for DTG or Direct to Garment printing. Rather than having the design printed onto a film, DTG prints the design right onto the garment without a DTF transfer. This is done by spraying ink onto the garment. Unlike DTF printing, DTG printing can only be used on cotton materials, preferably 100% cotton fabric. Businesses that sell more than cotton products, though, will find it in their best interest to use DTF printing. A DTG printer also costs more than an entire DTF kit, which makes it inconvenient for very small businesses.

What to Know When Preparing to Print

What exactly is needed when working on DTF printing? As mentioned in the step-by-step process section, more items other than just a printer are needed to successfully complete a DTF printing job. Here is a list of everything needed for your kit:

- DTF printer – This printer should include CMYK and White ink channels (6 in total).

- Inks – It’s best to find elastic inks to prevent the graphics from cracking while being printed.

- Film – The DTF or PET film is what the artwork is first printed on.

- Powder – The adhesive powder to go between the ink and fabric.

- RIP software – If your printer has been modified to use DTF printing, software should be downloaded to accommodate CMYK and white colors.

- Heat press or curing oven – Used to help transfer the print and flatten the design.

When transferring your artwork onto the film, it’s also important to know what kinds of files are compatible with the printer. Some printers are modified for DTF printing functions, so RIP software must be installed to use the full CMYK and white inks. As for file types, they can be EPS, PS, PDF, BMP, TIF, PNG, and PSD files, but transparent background PDFs work best. The artwork files should be high quality for best results, with 150-300 DPI. This will prevent the finished print from looking fuzzy and cheap. Other things to keep in mind with files is that semi-transparent backgrounds won’t look as good as transparent ones, neon and saturated colors will appear differently once printed (the closest color pigment will be used), and sRGB color profiles will be easier to run with the software compared to large CMYK color files.

Advantages

Here are some advantages to using DTF printing compared to other printing techniques:

- No pre-treatment is needed, such as using rollers on the papers, which could cause linings on white layers if the paper slides.

- Direct to film printing can be used on all kinds of fabric and colors rather than standard cotton or polyester blends, opening your business up to more garment types and colors.

- There is a slight texture to the design when it’s printed and will be easy to wash and clean.

- The elastic inks used prevent the artwork from cracking, making it durable.

- Using this method is cheaper and faster compared to other printing types, making it a smart choice for small and large businesses on a tight budget.

Disadvantages

Like other printing methods, there are also some downsides to using this printing technique that you should keep in mind before using:

- The print will not be infused into the fabric, making it more noticeable that it has been printed.

- Compared to dye sublimation printing, the colors will not be as eye-popping.

- The printing method has more steps than sublimation or DTG printing.

- DTF printing is designed for use on clothing fabrics rather than more rigid surfaces.

How Direct to Film Printing Compares to Other Printing Methods

We discussed above how DTF printing compares to DTG printing, but how does it compare to other commonly seen printing methods? What’s the difference between these techniques when it comes to their process and advantages/disadvantages?

Direct to Film vs. Dye Sublimation

Sublimation printing has become one of the most popular methods of custom printing. Dye sublimation printing is when the ink is ingrained directly into the materials, making the artwork appear like it is part of the fabric because there is no texture. This differs from DTF, because there is a textured feel to the finished product. While the result of sublimation printing might be more high quality, the process is more expensive and takes more time than DTF printing. Special paper is used for sublimation, which binds the ink into the material in a heat press. This type of printing can also be used on many surfaces but is best on polyester materials while DTF can be applied to all kinds of garments. You’ll often see sublimation printing on tablecloths, mouse pads, mugs, etc. Large businesses might incorporate both DTF and sublimation printing to accommodate a wide range of products, but small businesses might just use DTF printing to save on costs and time.

Direct to Film vs. Screen Printing

Another very common printing process used is screen printing where ink is pushed onto the fabric with a stencil or screen. A different screen is used for each color and the ink lays over the fabric rather than being infused directly into the material. This can make the clothing have a strong feel to it depending on how colorful and detailed the design is as more screens are used. This method contrasts to DTF printing, which does not have the thickness of the artwork change when more color and details are used. While screen printing is common, DTF printing is easier because it does not require changing screens for different colors. Screen printing is best used for large designs without much detail, such as shapes and logos.

Direct to Film vs. White Toner

White toner prints feel like DTF, but the main difference is the printing process. White toner requires laser printers, which are often more expensive than those used for DTF printing. The white toner process is more time consuming as weeding is done on the printing papers. If the weeding is done incorrectly, it can result in damage, which makes it much more complicated and stressful than DTF. Also, white toner prints don’t use elastic inks, so the print is more prone to cracking. The main reason why white toner might be preferred to DTF is because the white color comes out very crisp and clean. White toner can also be used on more rigid objects compared to DTF printing, which opens the opportunity for customizing more items.

Many companies, if they have the funds, will have more than one printing process they can use for different products so that each print looks the best it can. Small or home-based businesses, however, might find it best to invest in just DTF printing for a start due to the low price and easier/fast process.

Conclusion

Direct to film printing is a great option for small and large businesses due to its inexpensive hardware and ability to be used with all kinds of fabrics. While it might limit you only to garment fabrics, it provides durable prints that are resistant to cracking and can be used with all kinds of fabric colors for great looking garments that are easy to sell. If you would like to start selling your own custom clothing or already have a business but omit DTF printing, think about all the options it will open to you and your customers.

Sources

- Direct to Film Printers Explained | The Printer DTF Process

https://coldesi.com/dtf-printing/direct-to-film-printers-explained-the-printer-dtf-process/ - DTF Printing: A Game-Changing Technique For Your T-Shirt Business

https://www.brildor.com/blog/en/dtf-printing-game-changing-technique-for-your-business/