What is Sublimation Printing? – The Ultimate Guide (2025)

Are you looking for printed products that are long-lasting and feature distinct colors and high-resolution quality? The best designed graphic apparel, home décor, and advertising displays use the dye sublimation process to achieve vibrant, everlasting graphics.

So, what is sublimation printing and why is it so effective?

All of the information you need to know is available right here in this comprehensive guide.

Table of Contents

What Is Sublimation Printing?

While the name might make the process seem complicated and techy, it’s actually quite simple to understand.

Sublimation definition: when a solid material turns into a gas without going through a liquid stage.

This means that the artwork is transferred to an object in a gas state by using a high temperature heat press during the dye sublimation printing process. It differs from traditional printing methods because it bypasses the liquid step. There are no special inks drying to the printed object.

How Does Sublimation Work?

The image is first infused onto the source printing paper, leaving little mess and making the whole process quick and easy for dye sublimation printing. Heat is then utilized to transfer the image from the sublimation paper to an object.

Businesses and home designers use this sublimation process when creating graphics on clothing, as well as signage, home decorations, company exhibits, and personal items such as coasters, coffee mugs, and keyrings.

Sublimation 101 Video

Dye Sublimation Printing for Businesses: What Products Can You Print On?

Below is a list of profitable items that businesses dye sublimate:

- Rigid Substrates – Polymer treated objects that include non-fabric items like glass, plastic, fiberglass, and aluminum. These are products that aren’t bendable like fabrics.

- Blank Rigid Products – Many of these materials are available to buy in bulk at wholesale prices, like custom mouse pads, cell phone cases, and drinkware. They are sometimes referred to as “blanks”, which are products without any designs or printing included so that personalization can be added.

- Signage – Perfect for “click to print” e-commerce businesses. Easily print on vinyl to create retractable banners and other trade show displays. When seeing signs hanging in front of shops or buildings, there’s a good chance that sublimation was used.

- Polyester Fabrics – One of the most popular items to dye sublimate. They are divided into two types:

- Knit: Polyester products that hang & flow in their natural environment, like apparel, flags, banners, and custom printed table covers.

- Woven: More durable products such as custom tote bags, fabric backdrops, and custom tents.

- Home Decor – The dye-sub process is often used by businesses that sell to interior designers. Decor items like ceramic floor tiles are a popular choice for bathrooms, kitchens, restaurants, & more.

- Photograph Printing – Arguably the best way to produce the highest-quality photographic images on canvas, magnets, and apparel.

What Do You Need?

In order to make this form of printing possible, there are five essential tools needed.

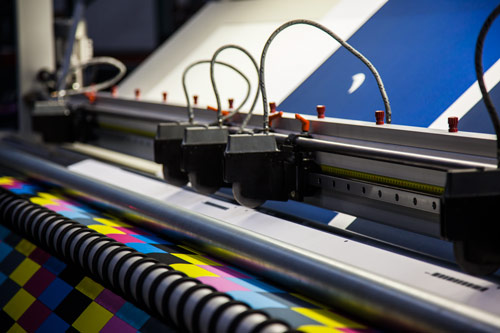

1. Sublimation Printer

First of all, the most important item would be a sublimation ink printer. This type of technology is created for both home and factory use. Just a few years ago, these sublimation machines would be very expensive. With the increase in demand of printed products, these types of printers have significantly reduced in price. Popular sublimation printer brands include Mimaki, Mutoh, and Durst. Some inkjet printers can be converted to sublimation, such as Epson.

2. Sublimation Paper

With the sublimation printer, any spectrum color can be created and transferred onto printing paper suitable for the machine. This type of paper is referred to as sublimation paper or transfer paper. One can print a personal work of art, a customized logo, a family picture, or any design desired for use onto the paper like they do with office paper.

3. Computer & RIP Software

Some sublimation printers include software necessary in setting up what will be printed out. These computer programs are called RIP software, short for ‘Raster Image Processor’. Not all printers include this addition, but RIP can be purchased separately. It needs to be stressed that the software must be compatible with the type of printer being used.

4. Cutting Mechanism

Other recommended items for sublimation include a cutting device, whether it is a knife or a rotary blade. This is required when creating original fabric items. There are some cutting products that include more than one option in one system to suit all needs. One would also need a sewing machine for hemming the material. This is particularly necessary when creating SEG (or Silicone Edge Graphic) frames.

5. Type of Heat Press

Another necessary item for printing is a heat press, which is the next step in the sublimation process after printing. Like the printer, sublimation transfers come in a variety of sizes, models, and prices to suit all needs. The function of the heat press is to remove the design from the sublimation paper onto the requested material, such as coffee mugs, t-shirts, and tablecloths. By doing so, this will create an item with a more vivid image that is resistant to fading, making it more durable for the long run.

When it comes to dye sublimation, there are four types of sublimation transfers that can be used:

Calendar Heat Press

When sublimation printing on larger, though softer, material, such as for fabric signs, a calendar heat press would be the choice. This press is bigger and accommodates printing on clothes as well as banners.

Small Heat Press

If sublimating on just little items, such as creating a design on handheld kitchenware, a small heat press would be suggested. This press doesn’t take up a lot of space and can incorporate pressing different types of items.

Flatbed Heat Press

For harder material, such as floor tiles and similar home décor, a flatbed heat press would be recommended for sublimation. This type of press is versatile and also suits printing on apparel.

3D Vacuum Heat Press

Finally, if dealing with smaller objects with more diverse shapes and edges, a 3D vacuum heat press is the way to go. This type of machine was designed for sublimating on surfaces that aren’t flat, opening the field of printing to a wider range of products.

What Are the Benefits of Sublimation Printing?

Here’s the deal:

If one wants the best-looking printed component, dye sublimation is the way to go.

By using this method, images won’t crack or wear after several uses and the visuals will last as long as needed.

This is very important for using with items that will be used constantly over time. Everyday items like mouse pads, kitchenware, and custom all over print shirts will benefit from this type of printing. This is especially true with apparel and bedding, as they can be washed on a regular basis without fear of distorting their appearance.

As mentioned before, dye sublimation can be done on much more than fabrics, which is the restriction of just heat transfer printing. If one really wants to get creative with what they want to print on, such as creating puzzles or personalized keychains, dye sublimation is the main option to choose. It leaves countless printing opportunities that come in handy for crafting and business presentations where customization is a bonus.

What Are the Cons of Sublimation Printing?

When looking at the pros and cons, the major con of sublimation printing is that it is expensive. While dye sublimation printers are made for household as well as professional use, they can cost around $300 for a small home one and can go up to $600 for a more high-end product.

For larger printers for mass production, they can cost up to $10,000. Keep in mind, however, that this is remarkably less steep than what they were a few years ago, but one has to remember that this is just for the printer alone.

Other required products include a heat press and printing paper, which can significantly bring up the cost. Well-made heat presses can cost from $150 to $500, and the sublimation paper used for the printer can be worth over $100 depending on how much you need.

Printing paper must also be purchased sparingly as opposed to the machines used. It must be noted that the price of this equipment is worth it in the long run when it comes to the quality of the print.

Another noteworthy con is, as expressed before, that this type of printing can mostly be done on polyester fabrics. They need to be 100% polyester for the best outcome. If you want to print on items that aren’t made from fabric, they must be poly-coated for the process to be most efficient.

Dye Sublimation vs. Heat Transfer

What is the difference between sublimation and heat transfer? The two types of printing can be confused with one another due to similarities of using heat presses, but the differences are HUGE:

Heat Transfer Differences

Transfer Paper

The main difference is that heat transfer paper makes the design an added coat on top of the fabric material when applied with a press. Think of the cheap, overpriced merchandise you see at tourist shops when you go to the beach. The paper is very inexpensive, but that’s because it doesn’t have the quality of sublimation paper.

Printable Fabrics

Heat transfer can be used on a wider variety of fabrics and is less expensive, but the result won’t look as vibrant as when sublimation is used. Heat transfer can also decrease in quality over time with cracking and fading. That is why most companies prefer using the sublimation process over heat transfer printing.

Sublimation Transfer Paper

Sublimation transfer paper creates a result that feels like it’s part of the fabric or rigid object. This design is fully infused into the fibers or material that you are printing on which means that it won’t fade or crack over time. It doesn’t look like a cheaper sticker was heat-pressed to the material. The end result is incredible.

Sublimation vs. Traditional Screen Printing

Screen Printing Process

The screen-printing process involves using a mesh stencil that pushes the ink onto the fabric. This is typically done with t-shirts and other fabric garments. Screen printing isn’t expensive but does require a new stencil for each design needed and for each color used. Since it’s a stencil, graphics are usually kept simple with not a lot of different colors. This is like how stencils are used for drawing, there isn’t a lot of room for different, more intricate designs. Using dye sublimation printing offers more opportunity for creative, colorful designs.

Printable Fabrics

While sublimation needs to be done with polyester or poly-coated items, screen printing can be applied to anything if the surface is flat. While this opens the door for more fabrics, like cotton, screen printing isn’t typically done on more rigid surfaces, such as mugs or textured tiles. This is because a flatter surface is needed for the best results, or else the image might be distorted. That is why this form of printing is typically done on clothing and is usually restricted to designs using one color. Sublimation, on the other hand, comes off best when more color is used and the designs can be very detailed.

Why Sublimation Printing is Better

Sublimation offers more room for creativity and unique designs that utilize full color printing. The field of what can be printed on is also more fast compared to screen printing. For quick, simpler designs, screen printing can be useful. But, for the most part, sublimation is the better option in most cases.

What Materials Can Be Sublimated?

I can’t emphasize this enough.

Dye sublimation is a very effective printing process that creates expert-level graphics, but there are limitations to what features it can be used with.

It is very important to note that dye sublimation should be used with polyester or polyester-coated material. While this can be confining to the kind of fabrics that can be applied, it leaves the field wide open for other non-fabric opportunities, such as trade show displays, tiles, and sporting goods.

These materials are unable to be printed on when using the other well-known printing processes, heat transferring and screen printing.

Some polyester-coated materials require different techniques when using the sublimated method.

Sublimation Printing on Fabric

There are several things to learn when using dye sublimation on fabrics for items like, T-shirts, dresses, tablecloths, custom tents, etc. “All-over” designs where a pattern or image covers the entire print are a popular option when using this process, as it’s easy to do. Dye sublimation is especially effective for printed fabrics used in outdoor signs like feather flags and 3×5 flags because it produces such vibrant, high-definition prints. Passerby can easily see the branding printed on dye sublimated feather flags, making the flags more effective at advertising for the business and spreading brand awareness.

Some hindrances that can occur when printing on fabric is that random white creases can appear on the printed fabric. This is usually due to not setting the transfer paper correctly, causing it to be folded over or become wet. One must be attentive when setting up prints for sublimating.

Also, if someone wanted their graphic to be slightly textured, this kind of printing isn’t the right choice as it’s for replicating the look, not the feel. One must use their best judgement when choosing a design to appear on a shirt.

Sublimation Printing on Glass

Since glass can break easily, it is important that more caution is taken when using dye sublimation printing. The heat press needs to be used carefully. The heat press pad can provide extra covering for the glass, but this isn’t required.

Another thing that must be remembered when printing on glass is that the way glass heats up is different from the more conventional fabrics often used. Occasionally, the heat can cause foggy sections in the print, so halftones can be used to cover this issue.

Another solution to the problem is using textured material that leaves the impression of a clearer image. Something that makes this approach different is that the sublimation ink must be in the right-reading style, since the print transfers to the back of the glass and is viewed from the other side. Other materials require the image to be sublimated in a mirror-image format.

Sublimation Printing on Plastic

Printing on plastic materials can require a different type of technology. While the heat press used for fabrics and other flatter surfaces is a flatbed press, if a 3D object is being sublimated printed on, an oven press would be required instead.

Another change is that the image will be printed on film rather than paper, which is more formable to the object being printed on.

A final thing to consider is that the item must be able to withstand around 400⁰F of heat without being ruined. This can be rarer in plastic products than in fabrics and glass.

Sublimation Printing on Aluminum & Metal

Using aluminum or metal items can create a very dynamically printed image. Choosing high-quality materials to be printed on offers the best results.

For the most beautiful effect, an efficient sublimation printer should be purchased. One with an 8-color setting is recommended.

Something that should be kept in mind is that metals are usually placed on top of the sublimation transfer paper instead of underneath when printing. Make sure the image remains properly placed on the material without using heat tape.

Overall, one has to be sure that the heat is directly touching the metal and the paper.

Sublimation Printing on Canvas

The main difference when using dye sublimation on canvases is that canvases can be designed to be stretched. This process is called a “Gallery Wrap”, which is when the canvas print is rolled around the sides to the back of the frame so that the tools used in securing the canvas can’t be seen by viewers.

One must keep in mind that the sides will be visible and also need to be printed on with either a continuation of the front image or a repeat of the same image. If using this gallery wrap style, then the canvas material should be larger than its frame so that it can stretch easily.

When preparing to use the heat press, it is very important to make sure the material is clean. This can be done by using a lint roller.

Sublimation Printing on Wood

The sublimated printing technology has even extended to wooden items, which leaves the field even wider open for what can be printed on. While wood doesn’t contain polyester, like a lot of other products, it can be coated with a poly substance by using rollers and heat.

Once when this is done, completing the sublimation process is similar to working with other polyester materials. The coating might allow the heat press to be used at a lower temperature than the standard 400⁰ most other products use. This should be looked into when using certain coating on wood.

Sublimation Printing on Acrylic

While acrylic isn’t polyester based, there is a product referred to as Sublimation Acrylic that can be used for the dye sublimation process. This product can be used with the conventional heat press and transfer paper without being ruined. Sublimation Acrylic is sold on sites and in stores where they sell printing materials and machines.

Sublimation Printing on Vinyl

The vinyl sublimation process is done almost the same as with other materials. The main difference with vinyl is that it’s used on products that are cut in shapes.

This often applies to products that use sticky adhesive, such as wall and floor decals. This is done by cutting the silhouette of the image wanted on the design file before using the sublimated printer.

When it’s time to sublimate, the vinyl is cut into the proper shape. Cutting should be done close to the edges of the print. Depending on the size, more than one vinyl product can be printed at once and cut separately.

Sublimation Printing on Nylon

This is the most difficult material for dye sublimated printing. There are many different types of nylon, each with a different reaction to the sublimation process. Nylon 6 is the type that is most commonly used for textiles.

Something to keep in mind with nylon printing is that it needs to be tried and tested to see what the most attractive result is. There are unique outcomes for the wide range of options available. One helpful tip would be to use lower heating temperatures.

Why Choose Dye Sublimation Printing?

Look, dye sublimation may be more costly than something like heat transfer printing, but it creates a better looking image that can be used for years.

The options of what can be printed on are much wider than with other more affordable printing procedures, leaving more room for innovation.

If you want something that requires use over a short period of time, then something like heat transfer can be recommended.

If, however, you’re looking to print something that’s intended on being kept for a lengthy duration, and plan on washing it to keep it in pristine condition, then dye sublimation is the best bet.

Whether you’re planning on using sublimation to construct your own ideas, or if you are looking for quality made products, this information should be helpful in finding what you’re looking for.

Sources

- 3 Things You Should Know About Dye-Sublimation

https://www.rolanddga.com/blog/2016/06/02/22/42/3-things-you-should-know-about-dye-sublimation - 5 Things You Need to Know About Dye Sublimation Printers

https://itnh.com/blog/dye-sublimation-printer-need-to-know/ - Everything You Need to Know About Dye Sublimation Printing

https://www.asicentral.com/news/sponsoredby/itnh-inc/everything-you-need-to-know-about-dye-sublimation-printing/ - What Is Dye Sublimation?

https://www.heattransferwarehouse.com/blog/what-is-dye-sublimation - What Is Dye Sublimation Printing?

https://magicard.com/knowledge-centre/what-is-dye-sublimation-printing/ - Heat Transfer vs. Sublimation Printing

https://www.coastalbusiness.com/blog/heat-transfer-paper-vs-sublimation.html - Glass Decoration with Sublimation: A Clear Choice

https://graphics-pro.com/ - Understanding How Sublimation Printing Works

https://www.prodigi.com/blog/understanding-how-sublimation-printing-works/ - A Look at Two Different Print Technologies: Dye-Sublimation and UV

https://plasticsdecorating.com/uncategorized/2018/a-look-at-two-different-print-technologies-dye-sublimation-and-uv/ - Dazzle Customers with Sublimation on Metal

https://www.sawgrassink.com - Gallery Wrapped Image Canvas for Sublimation Imprinting

https://dyetrans.com/products.php?webmaincat=sub_prods&websubcat=gallery-wraps - Learn About Sublimation on Acrylic

https://www.bestblanks.com/blog/sublimation/on-acrylic/ - Sublimation Acrylic

https://www.dyesublimationsupplies.co.uk/ - How to Sublimate Heat Transfer Vinyl

https://specialtymaterials.com/how-to-sublimate-heat-transfer-vinyl/ - Is It Possible to Sublimate on Nylon?

https://batikinstitute.com/can-you-sublimate-on-nylon